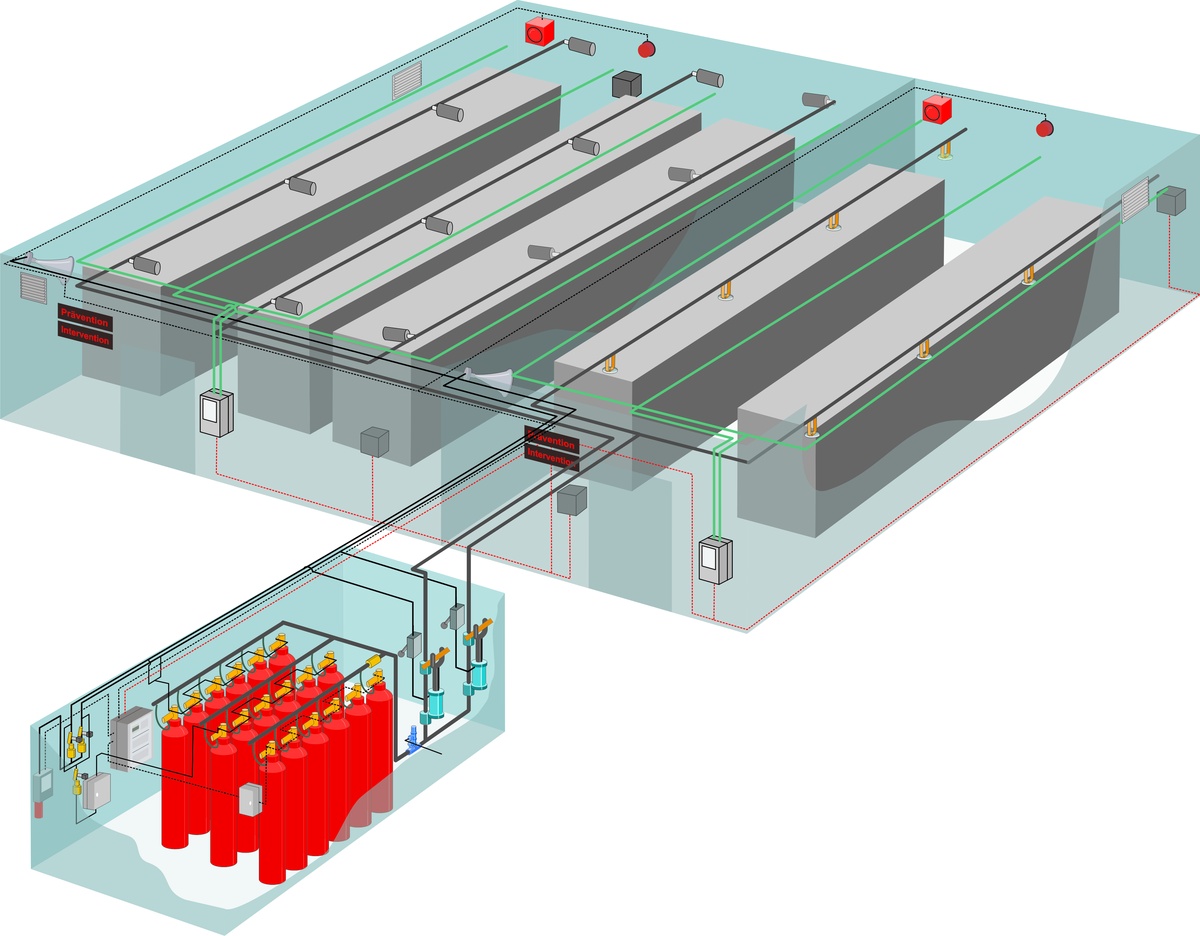

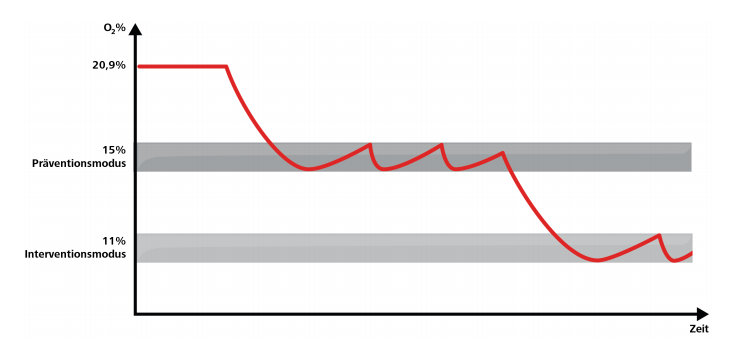

Thermolysis gases are released in the event of a fire long before aerosols or smoke particles are even generated. The Oxeo EcoPrevent CS system detects these thermolysis gases and reduces the concentration of oxygen in the affected protected area through the controlled supply of nitrogen to a level that ensures a "fire-proof" atmosphere. Thus the early detection of thermolysis gases is the best way to prevent the outbreak of an open fire. Oxeo EcoPrevent CS protected areas are freely accessible, since the oxygen concentration is only reduced when needed.

Advantages of Oxeo EcoPrevent CS versus inert gas extinguishing systems

- Less fire damage and consequential damage by preventing the outbreak of an open fire in prevention mode

- Supplementary inert gas provides time to locate the thermolysis event and to remove its cause

- Added safety for people through the controlled inflow of inert gas

- In most cases, the switch to prevention mode is sufficient in the event that thermolysis gas is detected. This results in lower costs for refilling the cylinder battery.

Advantages of Oxeo EcoPrevent CS versus systems with permanent oxygen reduction

- Prevention of an open fire without the permanent use of energy and maintenance of compressors, compressed air processing units and nitrogen generators

- Quick supply of inert gas in the event of an unexpectedly high intake of fresh air

- Additional backup via intervention mode

- In standby mode, the protected areas are generally accessible without requiring a prior occupational health check

- Modular extension of the inert gas supply