Fire detection and extinguishing control technology

The Minifog ProCon system is triggered by the proven Minimax fire detection and extinguishing control technology. This guarantees optimum compatibility of electrical and mechanical system components. Unnecessary expenditure of effort on coordination and interface issues between different contractors are thus avoided.

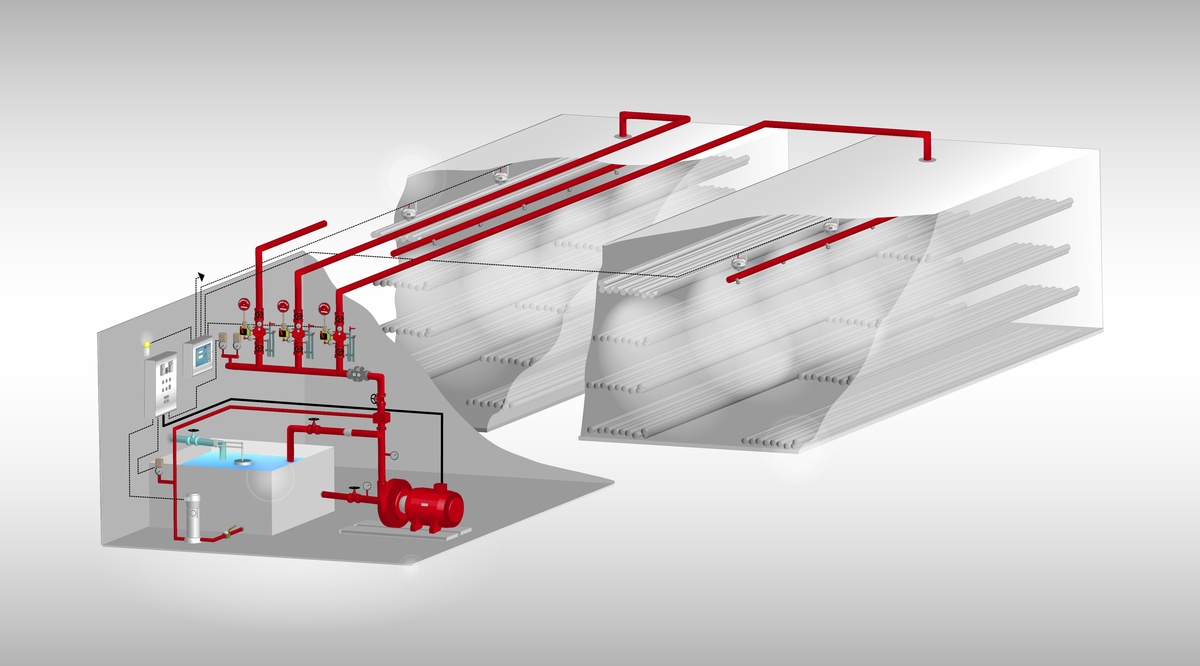

Fire detection is adjusted to the risk of the equipment to be protected - generally by means of electronic fire detectors which in the event of a fire send a signal to the FMZ 5000 fire detection and extinguishing control panel. This then activates the deluge valve for the affected extinguishing zone. At the same time acoustic and optical alarms are triggered and optionally forwarded to a permanently manned location, e.g. in order to alert the fire brigade. The right Minimax fire detector is ready for any application. In connection with Minifog ProCon water mist systems UniVario flame and heat detectors and HELIOS AMX5000 smoke aspiration systems are frequently the first choice.

Extinguishing zones and zone partitioning

In the extinguishing zones, ProCon fine spray nozzles are aimed at the facilities to be protected. On taller equipment they are also installed at several levels. In the event of fire the water is delivered as a mist into the source of the fire via all the ProCon nozzles installed in an extinguishing zone. This way, even quickly spreading fires can be suppressed.

Minifog ProCon systems can be designed both as a single-zone system for the protection of one extinguishing zone and as a multi-zone system for the protection of two or more extinguishing zones with just one water supply. Each extinguishing zone is assigned a deluge valve set which in the event of fire is triggered by the fire detection and extinguishing control technology and releases the flow of water only in the affected extinguishing zone. The more extinguishing zones are formed, the more targeted the extinguishing at the source of the fire and the less water needs to be used. Larger equipment is often subdivided into several extinguishing zones.

Water supply

The Minifog ProCon system water supply is generally via a storage tank with automatic refilling and a pump. Alternatively in many cases the system can be combined with a classic sprinkler or hydrant system to share the existing water supply. Minifog ProCon systems can however also be connected to a suitable service water network or – using appropriate safety equipment – to the public drinking water supply. Additional safety is achieved through feeding-in via a fire brigade supply which then also allows supply if for example the power supply to the pumps fails.

In the operational readiness condition the pipe network is filled with water as far as the deluge valve sets. In this case, a jockey pump - controlled via a pressure transmitter - maintains a constant system pressure of approx. 9 bar, which drops briefly in the event of a fire due to the opening of one of the deluge valves. Another pressure switch detects this and the main pump is activated via the pump control cabinet.