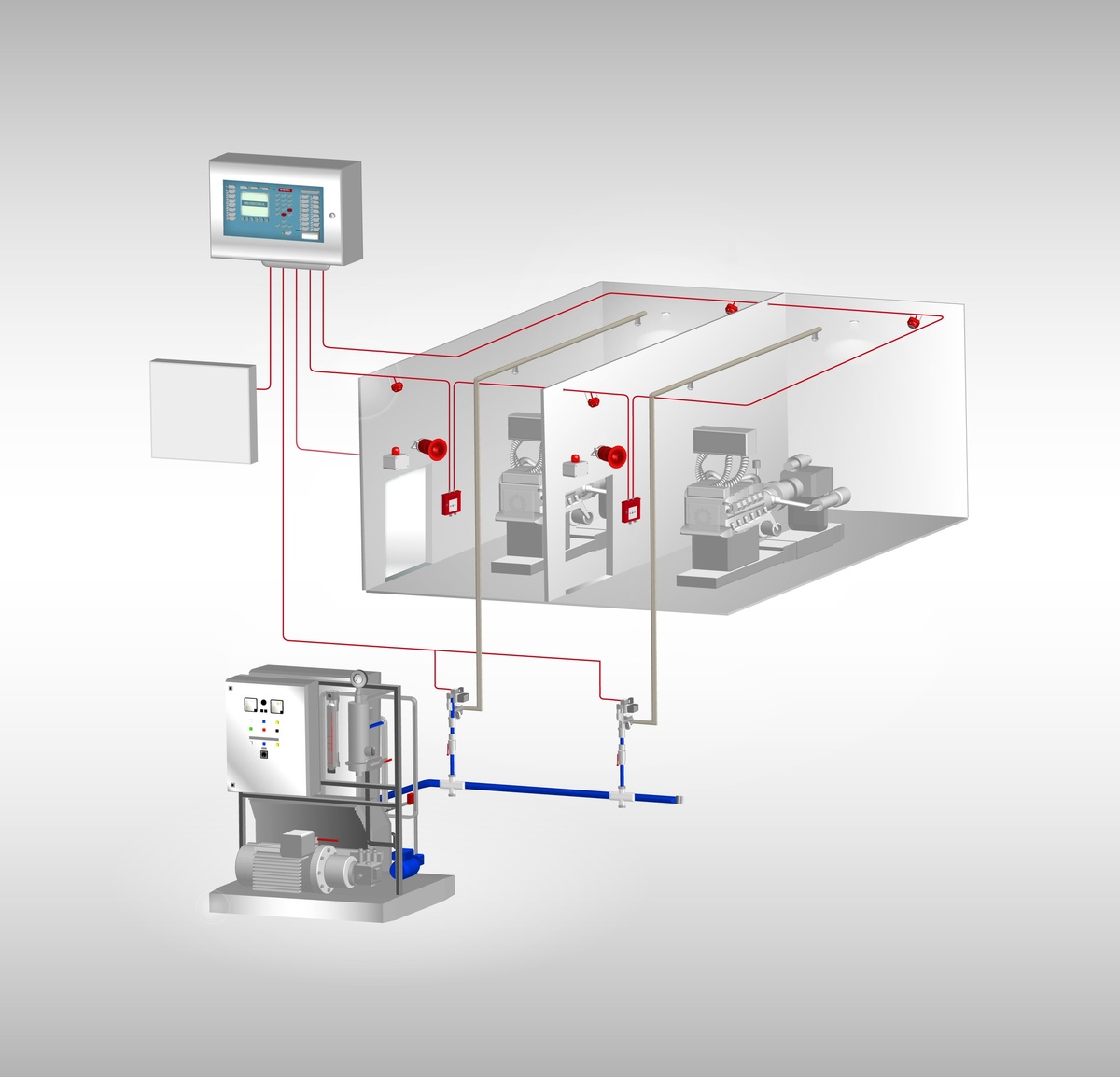

Minifog ProCon XP high pressure water mist systems offer excellent fire protection along with a minimum consumption of extinguishing water, e.g. for systems in confined spaces. Minifog ProCon XP uses approx. 95 percent less extinguishing water compared to conventional spray water extinguishing systems. This extremely low consumption of extinguishing water reduces the risk of water damage and thermal distortion of hot machine parts to a minimum. The water supply unit can be designed in a more compact format. This saves space, on-site costs and makes retrofitting easier.

Advantages at a glance

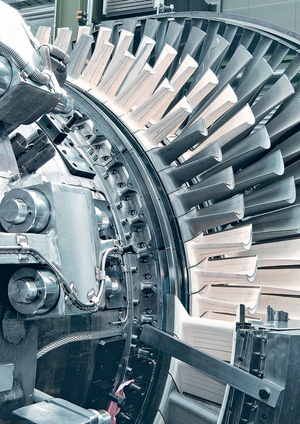

- Minifog ProCon XP protects engines, turbines and other equipment

- Substantial investments are protected and long and costly downtimes can be prevented

- The use of water means that no specific health and safety measures are required to protect people against the extinguishant

- Compared to classic water spray systems, Minifog ProCon XP reduces water consumption by up to 95%

- Minifog ProCon XP offers protection of large spaces with a dimension of up to 2,430m³ and a height of up to 13.5m

- The Minifog ProCon XP system can be designed as a multi-zone system even when the water is supplied via cylinder battery

- Enhanced protection against reignition: The ConstantFlow technology keeps the system pressure constant throughout the entire operating time even if the water is supplied via cylinder battery

- The use of the well-proven Minimax fire detection and control technology ensures optimum compatibility of electrical and mechanical system components

Design and installation

As one of the world's leading full-service providers in the field of fire protection, Minimax not only develops, produces and supplies the full range of technology components - from detectors to nozzles - for the Minifog ProCon XP high pressure water mist system, but also handles the entire project management, including planning, installation and commissioning as well as postsales service, to ensure optimal and consistent fire protection from a single source.