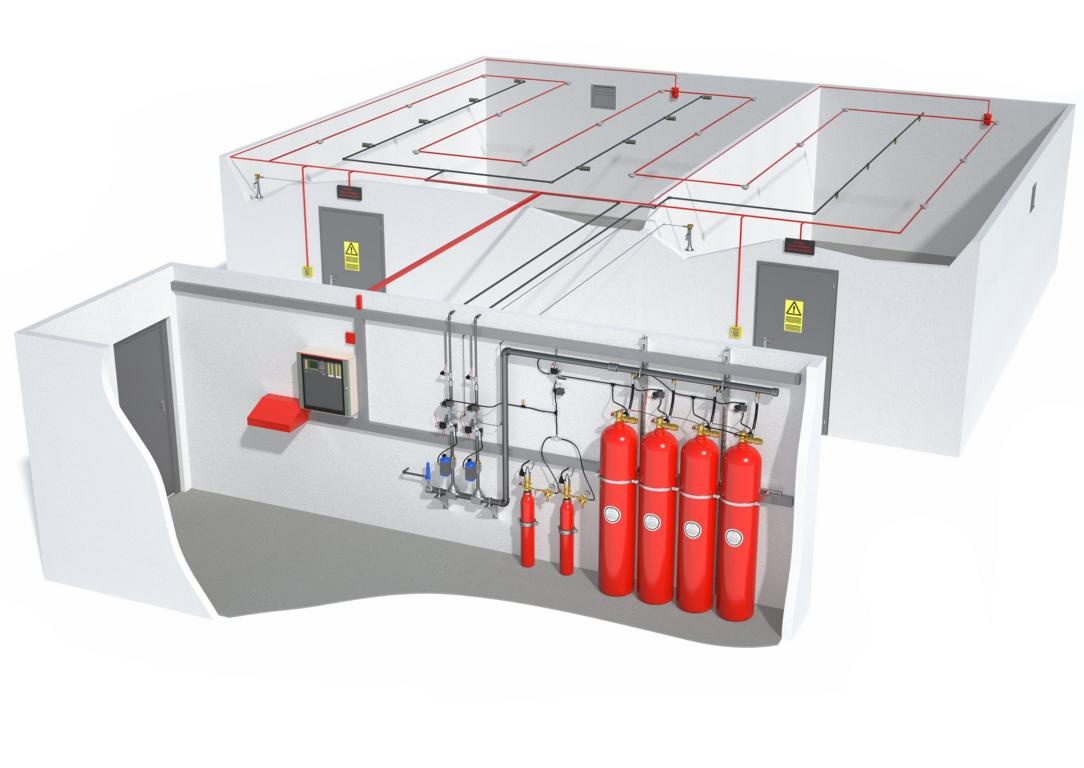

The inert gases used in Oxeo extinguishing systems are distributed homogeneously in the event of fire and displace the oxygen from the fire source. Thanks to the three-dimensional mode of action, even concealed fire sources are reliably and safely extinguished before re-ignition. For this reason Oxeo extinguishing systems are very suitable even for the fire protection of special risk areas with flammable liquids and other hazardous substances and of areas with high fire loading.

Rapid fire extinguishing with inert gases keeps damage caused by fire to a minimum. In addition to this – in contrast to water, foam or power – secondarydamage caused by the extinguishing agent is excluded: inert gases leave no extinguishing agent residues and can be simply removed from the affected area again by ventilation after extinguishing the fire.

Oxeo extinguishing systems are therefore always an out- standing solution if it is worth protecting valuable goods or irreplaceable cultural objects from being destroyed by fire. Moreover inert gases are electrically non-conductive, so that they can also be used in areas with electrical or electronic components. So Oxeo extinguishing systems avoid long downtimes and expensive interruptions in operations.

Advantages at a glance

Oxeo inert gas extinguishing systems utilize inert gases, such as argon or nitrogen, and the resulting reduction of the oxygen content. They are suitable for protecting areas with high-quality yet sensitive equipment, where residue-free extinguishing - without the use of water, foam or powder extinguishing agent - is to be preferred. Argon and nitrogen are natural components of ambient air and also non-toxic and non-electrically conductive.

- Excellent extinguishing effect even in special hazard zones and in areas with high or concealed fire hazards

- The inert gases used are non-conductive and leave no residues - this makes them ideal for the protection of highly-valuable and sensitive equipment

- In the concentrations required for extinguishing inert gases used are non-toxic and therefore suitable for use in areas that are accessed by people

- Nitrogen and argon are natural components of ambient air - no harmful impact on the atmosphere

- Nitrogen and argon are available almost everywhere - this means, quick and cost effective reactivation after operation

- Cost-effective multi-zone systems with extinguishing gas storage can be implemented for several extinguishing zones

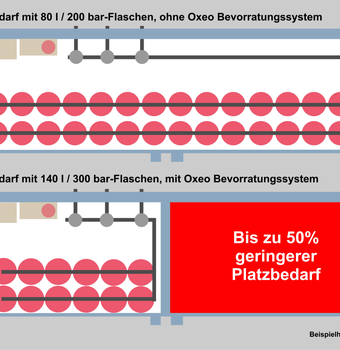

- High degree of flexibility for modification or extension measures, thanks to the Oxeo storage system

- Oxeo technology enables a more compact storage of the extinguishing agent, requiring up to 50% less space

- ConstantFlow technology ensures a constant flow of the extinguishing agent in the event of a fire - this permits the use of pressure relief flaps that are up to 70% smaller

- The MX DesignManager calculates the perfect system option and solution for every project

Do you have questions regarding the product or would you like individual advice? Please feel free to contact us!