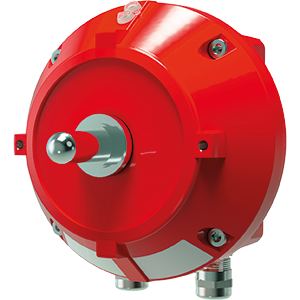

UniVario industrial fire detectors are intelligent, platform-based and microprocessor controlled fire detectors. Thanks to their modular concept and advanced signal processing techniques, these detectors meet individual requirement profiles within an exceptionally wide range of applications. UniVario industrial fire detectors work indoors and outdoors; likewise in the direct vicinity of the equipment to be protected as well as from larger distances. They are deployable in both clean room areas and under harsh process conditions as well as in explosion-hazardous areas, thus providing solutions to all requirements.

Advantages

UniVario industrial fire detectors are intelligent, platform-based, microprocessor-controlled fire detectors with a robust housing and assembly technology for even the harshest working conditions.

- Fast fire detection with a very low risk of false alarms

- High industrial safety

- Broad field of application

- Easy to adapt to changes in conditions

-

Low power consumption – potential for cutting costs

- Flexible connection technologies, simple installation

- Worldwide approvals

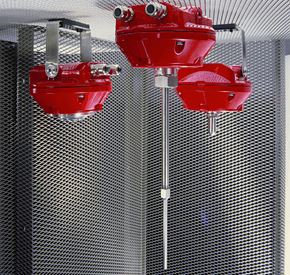

Fire detector with a modular structure

The combination of highly responsive sensors

and intelligent evaluation algorithms ensures that UniVario industrial fire detectors always detect fires very fast with a very low risk of false alarms. Their ability to intelligently suppress disturbance variables, high and very accurate response temperatures and the option to use the detectors in explosion-hazardous areas offer a very broad range of applications for UniVario detectors.

Application-specific configuration of signal processing and modularity permit easy adaptation of changing operating conditions. The high level of operational dependability is ensured by microcontroller-based function monitoring and the sensor test, as well as by the high degree of protection (IP66, IP67), oil leak tightness and a high level of impact and vibration resistance. The number of worldwide approvals confirms the quality and wide field of application.

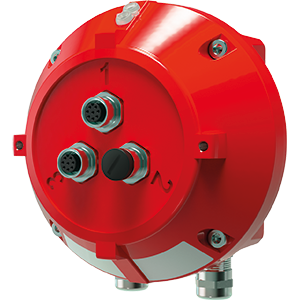

The communicative detector in the loop

By using communication modules, UniVario industrial fire detectors can be converted to full-blown analogue addressable detectors. As a result, and unlike most other available industrial fire detectors, these detectors can be integrated into the fire detection systems as full-scale detectors with a protocol merely by plugging in a module. Reported events can be assigned precisely to a detector, and the fire alarm and extinguishing control panel can initiate the required steps. UniVario detectors are the first industrial fire detectors where this option is available even for explosion-hazardous areas. The KMX5000 AP and KMX5000 AP Ex module allow to operate the UniVario industrial fire detectors as complete loop participants on fire detection control panels with Loop AP protocol – without required specific loop couplers.