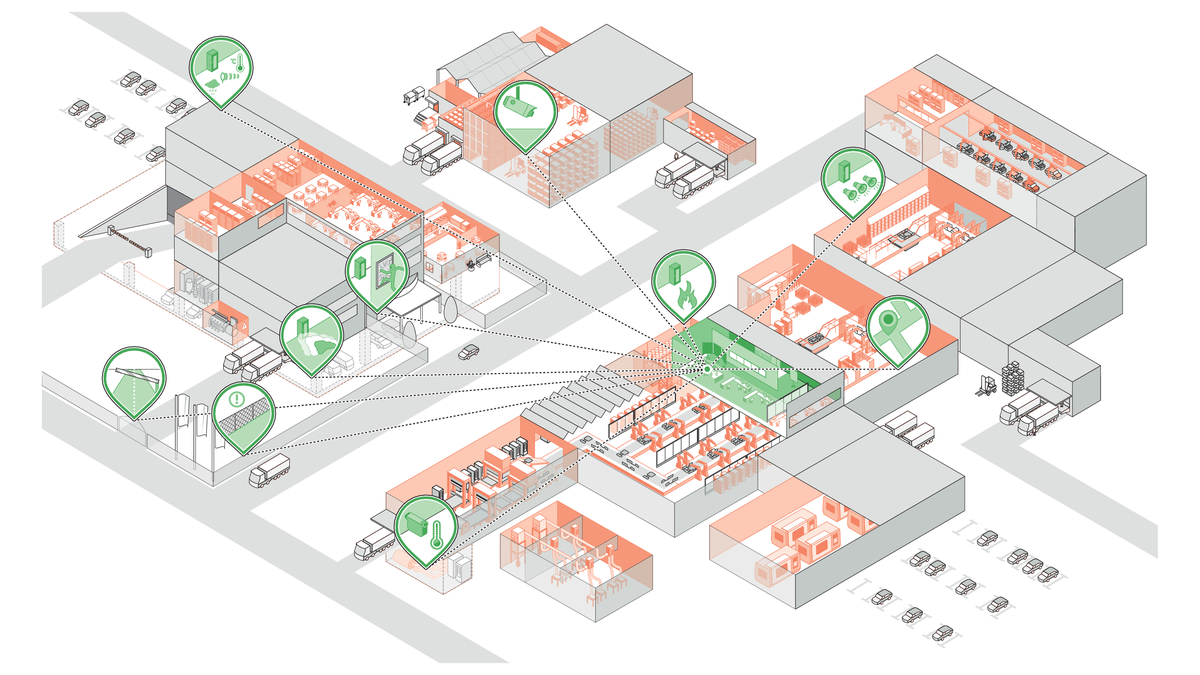

Inveron offers a high degree of clarity by bringing together all messages and events automatically in a user-friendly interface with clear graphics. The current status of control points can be displayed graphically, textually or as an animation. This applies both to messages for above and below threshold values, which are displayed in real time. The rapid localization of a problem is crucial in preventing operational downtimes. Inveron helps those responsible to make correct decisions in case of fire or malfunction.

Targeted action is possible and the highest level of safety is guaranteed. The system provides the operator with comprehensive continuous information such as reports on maintenance work and helps with on-screen messages. Action procedures can be stored and will be dependable guide to the necessary actions. Internal processes become more efficient and safer. Monitor globally, operate locally: With Inveron, several locations belonging to a company can be incorporated into an overall system, whether on the other side of the street or on another continent. Distances make no difference.

Authorization administration and data supply are centrally controlled. Each location only sees the information intended for it. Authorized operators can access all locations at any operator station and get a comprehensive overview. Operation is the same everywhere. It is possible to switch messages to another location if a security point is not manned. The information can be received by SMS or E-mail. Minimax can assist with service access for troubleshooting.

Advantages at a glance

Inveron is a transparent and user-friendly system for visualizing and operating fire detection, extinguishing and hazard detection. All reports and events are automatically merged in a user interface and presented on a screen. Inveron offers ideal monitoring particularly for complex building structures. In addition, the hazard management system supplies operators with a range of additional information and supports them in carrying out the required measures.

- Cross-system integration of all messages in one interface

- Easy visualization

- Rapid localization of fire events and faults

- Stored action instructions help to prevent mistakes in stressful situations

- Efficient preparation of route guides

- Location-independent monitoring

- Event evaluation through automatic logging